Paul Beck is an expert at stopping leaks in wing tanks

There is no shortage of unusual businesses serving the general aviation industry, but sealing wing tanks for a living must be on everyone’s short list. That’s because it’s so difficult since our tanks are sealed inside the wings and the access ports are made for Cirque du Soleil performers.

Flying halfway across the country in a friend’s Mooney M20C, I vowed to hire someone to fix my M20F’s leaky tanks. This revelation occurred after he “repaired” the right tank himself and it leaked like a sieve. “I don’t know what went wrong,” he told me as we descended for yet another fill up. “I removed all the inspection panels and spent hours scraping out the old sealant. It was horrible having my arm jammed in the tank for hours. I thought I did a good job cleaning everything and re-sealing it.”

Obviously, he was wrong.

I purchased my 45-year-old plane last November in Minnesota to lower flying costs after owning a gas-guzzling, maintenance-loving Cessna 210. I knew wing leaks were an issue with Mooneys as they age, just like incontinence afflicts older people. Although some minor wing staining was evident in the pre-buy, nothing seemed to require immediate attention. When it showed up under the area my rear end occupies however, that was motivation to “permanently” fix the problem.

Mooney wings leak for several reasons. Polysulfide sealant covering seams in the tanks can last 35 years or longer, but deteriorates if the plane is in a hot environment or if tanks are left empty and dry out for long periods. The bigger culprit is our stout landing gear, which transmits stress into the wing spar. Every touchdown causes the sealant to flex and stretch. As that material gets older and less flexible, fuel can start dripping, weeping or streaming from tanks. This problem isn’t unique to Mooneys. Certain Cessnas, Pipers, Grummans, Commanders, Vans, and most jets have wet wings.

According to Mooney service notes, there are three classes of leaks: Stain, seep and running. The factory considers even a running leak OK as long as it’s outside the slipstream and not entering the cabin. Be aware there’s a quarter-inch hole near the front of the wing that can create a pathway down the spar into the carpet. If your plane sits for a few weeks and you open the door and get a whiff of fuel, it’s in the cabin.

If you’re OK wiping off occasional stains or living with a few drips, it’s possible to go several years without taking major action. However, fuel can work under the sealant and loosen it so much that a ferry permit is needed to travel.

If you’re OK wiping off occasional stains or living with a few drips, it’s possible to go several years without taking major action. However, fuel can work under the sealant and loosen it so much that a ferry permit is needed to travel.

Temporary patch jobs can be done, but your mechanic better be 100% sure where the leak is to seal the right area. That’s confirmed by drawing a low pressure vacuum in the afflicted tank. (Every Mooney has one tank in each wing. They run approximately five feet out from the wing root, and can have three to six bays.)

I didn’t want a temporary fix since properly sealed wet wings can last for decades and my goal was flying, not visiting my friendly A&P. With that in mind, several options were evaluated, which cost roughly the same amount.

Bladders are popular with some pilots, but they weren’t what the factory originally designed and I was paranoid about getting a wrinkle that could trap water. They also reduce useful load and require some permanent wing modifications. Plus, AD 24-25-04 issued in January 2005 required some modifications by bladder owners and I’m phobic about the impact of ADs on my plane’s value.

Sealing the original tanks was my preference, but it requires removing all the old sealant. Someone can manually scrape and/or grind it out. Or it can be dissolved with special chemicals.

I started my career with Alcoa Aluminum in Davenport, Iowa, where we produced wing skins for Boeing jets. Aluminum is a fabulous metal but it can be scratched and corrode. The thought of someone scraping the old sealant inside my plane’s pristine wings for dozens of hours — or attaching a circular, wire brush to a drill and removing metal along with old sealant — wasn’t for me.

That left one choice: Chemical stripping at Weep No More in Willmar, Minnesota, 80 miles west of Minneapolis.

The company began life in the 1990s as part of Willmar Air, which was owned by Bruce Jaeger, a well-regarded Mooney expert. They used pieces of old aircraft windshields that were honed to an edge as scraping tools. It was miserable work, taking roughly 90 hours per wing to remove old sealant. Jaeger thought there had to be a better way to remove sealant and set out to find it.

The company began life in the 1990s as part of Willmar Air, which was owned by Bruce Jaeger, a well-regarded Mooney expert. They used pieces of old aircraft windshields that were honed to an edge as scraping tools. It was miserable work, taking roughly 90 hours per wing to remove old sealant. Jaeger thought there had to be a better way to remove sealant and set out to find it.

By 2000, proprietary chemicals were developed, along with a special machine that could apply them continuously. The in-house expert was Paul Beck, a machinist and A&P who joined Willmar in 1995 when he was 22. He now owns Weep No More and has repaired and sealed 500 Mooney tanks and patched another 100. That’s probably more than anyone in the world.

To fix leaking tanks, the access panels are removed so the machine can interface with the wing. In the case of my plane, a hose was introduced that went into all three bays of each tank. The machine then sprayed several gallons of the cleaner continually for six hours, dissolving the sealant without any scraping.

“The key to success is keeping the inside of the wing wet so the chemicals do their work and expose all the seams,” Beck explained.

After six hours of continuous chemical cycling per tank, he pressure washes them for 15 minutes. The stripper is deactivated when the water hits it and a ceramic heater is introduced to evaporate all the moisture.

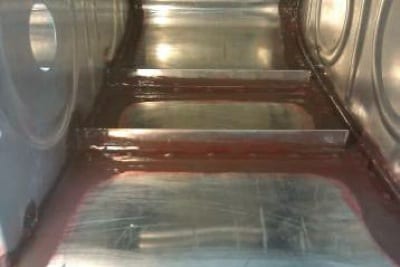

Looking inside several cleaned tanks, they looked absolutely brand new — no scratches, no gouges, no rough spots, and they reflected the flashlight beam like mirrors.

Seam sealing begins using the same protocols and FAA-approved materials as the factory. The three-part process starts with a thick sealant that’s deployed with a pneumatic caulk gun. An acid brush is used to flatten that bead out so it’s squished into the seam. Twelve hours later, a second sealant is applied over the first with an acid brush. After that cures overnight, a final sealant is applied. It’s the color of dark blood and the consistency of honey. (Paul told me he’s seen some tanks that were entirely sealed by their owners. He said that’s a recipe for disaster and a huge waste of materials.)

The access panels are also sealed, but the material is low adhesion so they can be easily removed in the future. Only the wing walk panel gets a high adhesion sealer since that has people stepping on it and only comes off for major wing work.

The fuel senders are then reintroduced with new gaskets, and new quick drains are installed. I was pleased to discover my fuel gauges started working properly after the tanks were sealed. I also noted that the wing seam and screw heads were touched up with paint that perfectly matched, and the wing walk was painted with new, textured black paint. In short, everything looked perfect.

The tanks are then filled to the brim and sit for 72 hours to confirm there are no problems. It’s been several years since Beck has had a leak, and his work is guaranteed for five years, so I was confident I could fly five hours back to Texas without worrying about a return trip.

The tanks are then filled to the brim and sit for 72 hours to confirm there are no problems. It’s been several years since Beck has had a leak, and his work is guaranteed for five years, so I was confident I could fly five hours back to Texas without worrying about a return trip.

A standard Mooney should be left at Willmar for two weeks. Anything bigger than a J Model should stay for three weeks since there are six bays per side instead of three.

There are several ways to reach Willmar, including flying to that uncontrolled airport and catching a shuttle or ride back to Minneapolis International. Transportation back to Willmar a few weeks later is easily arranged.

Sealing both my tanks cost $7,400 but I don’t have to worry about them for the rest of my life, particularly since I’m about to replace the landing gear discs and will henceforth grease every landing. Well, almost every landing.

For more information: 320-295-1671, WeepNoMoreLLC.com

Kevin Knight is an instrument-rated pilot in Texas who earned his license in 1985.

People who read this article also read articles on airparks, airshow, airshows, avgas, aviation fuel, aviation news, aircraft owner, avionics, buy a plane, FAA, fly-in, flying, general aviation, learn to fly, pilots, Light-Sport Aircraft, LSA, and Sport Pilot.