When Joy Hobbs sent in a photo of her grandfather and his co-workers by Lycoming’s XR-7755-3 engine, it attracted a lot of comments from General Aviation News readers.

First of all, I’d like to thank those readers who submitted comments to the Letters to the Editor column regarding “The men who built the largest piston engine in the world” that Lycoming built in the mid 1940s.

Just to clarify: This was not the largest engine ever built as was pointed out by one of our readers. It was, however, the world’s largest aircraft engine ever built at that time.

The thing that has always amazed me is the fact that this massive engineering feat was done without computers, Cad/Cam systems, and the many other technical devices that are commonplace in our industry today.

This engineering design took place over a relatively short period of time — 1944 to 1946 — and was done using only good engineering practices and a slide rule.

As I may have mentioned in the past, my dad was a member of the engineering group. As a draftsman, one of his jobs was to lay out the reduction gear assembly for the blueprints that would be made as a part of the assembly process.

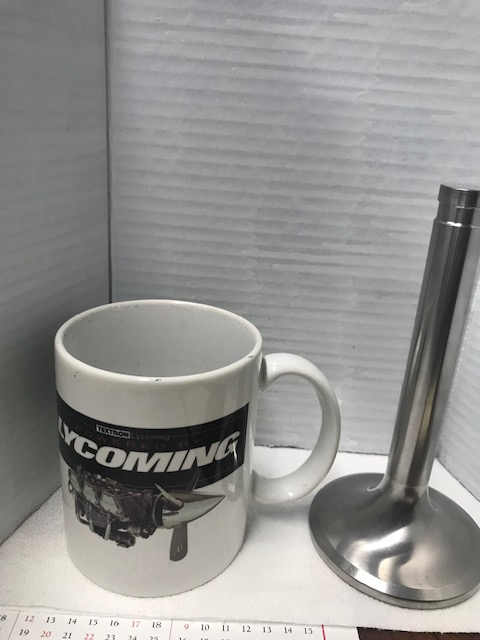

I’m fortunate to have a copy of those blueprints, along with one of the intake valves used in the engine. Since most of you are familiar with the intake valves currently being used in today’s aircraft engines, I’m sure this photo will come as a shock.

The dimensions for this XR-7755 valve look like this: The valve stem is 6.5 inches long and the stem diameter is ¾ of an inch. The actual valve face measures 3-¼ inches across.

Each one of these intake valves weighed approximately 1.2 pounds. Taking that weight into consideration, it’s not difficult to understand why the dry weight of this monster engine was about 6,000 pounds.

As we know, this engine was initially designed for installation on the Convair B-36 bomber. It was a tremendously large aircraft that would have had six of these gigantic engines installed. I can’t even begin to estimate the total gross weight of the aircraft we’re looking at here.

If the XR-7755 weighed 6,000 pounds dry and we now add the engine oil (I never heard the total gallons), we’re looking at some pretty big numbers. Since the XR-7755 was a liquid-cooled engine, we’d also have to add the weight of the liquid coolant to the equation as well.

Again, I have never heard any weight figures for the coolant fluid, but I know to keep the engine temperature within its operating limits, the coolant pump had a capacity of providing 750 gallons per minute.

As I mentioned in some of my previous writings about this engine — and to give you some perspective of this capacity — you could nearly fill a standard railroad tank car in about 10 minutes. This 750 gpm capacity is very similar to present-day fire truck pumpers.

Just take a moment and think about this: This engine featured nine dual-lobe overhead camshafts, which shifted axially for takeoff and cruising efficiency, and a two-speed, geared, dual-rotation propeller drive.

When you stop and think about it, this was one heck of an undertaking for Lycoming and the people involved in the program. I consider myself so fortunate to have been able to work alongside some of these great team members during my time at Lycoming.

It’s too bad that these engines weren’t retained as an example of what could be accomplished during that time period in history. The sole surviving engine is on display at the National Air and Space Museum’s Steven F. Udvar-Hazy Center in Chantilly, Virginia.

I must say that while this exhibit is something to see, I wish the engine was actually mounted in a horizontal position rather than the present vertical configuration to give viewers a better perspective of how large this engine actually is. Its present display configuration may be due to space limitations, but regardless, if you ever get the chance to visit the facility, I can guarantee you’ll find it educational and informative.

Oh, one more thing before I close. My dad told me that there was a target date to complete various stages of this engine and if that date were met, the entire group would get a bonus amounting to one week’s pay.

Fortunately, my dad was in a group that met the date, and he was rewarded with one week’s pay for a total of $15!

only 2 made ? well the idea of fitting one to my 172 is gone .

Still, having this engine in the B-36 would have solved some of it’s issues such as overheating, and general reliability because of the cooling issues. An extra 1200 HP per engine would have been nice.

I can’t recall, as it’s been some time since I’ve been there, but I thought there was one of these engines in the museum room at the Lycoming factory on Oliver Street in Williamsport!

Thanks Paul, that was great. As a docent at the Udvar_Hazy Center of NASM, when I get visitors interested in our engine section, I always make sure they see the XR-7755. Do you know of any books out there that give more information on the topic?

15$ the good ol hard times 😉

Chanute air force base in rantoul Illinois had a B 36 on static display.My last google search showed it still there. I walked around it often when I was stationed there.

I stopped by the Chanute AFB museum in 2015, before it was closed. I couldn’t find the B-36 then. I asked at the museum and the lady there didn’t know anything about it. After an internet search, I found it was disassembled and moved to Castle AFB, CA years before. I was at Chanute AFB for the jet engine mechanic training, before I went to my reserve unit at Rickenbacker ANGB and worked on C-123K’s. I eventually switched to the Army and retired in 2008.

In 2007, I went through the Lycoming engine course and part of it was the factory tour, they had one of these engines on display there.

Wow!!! GOD created mankind, in His own image and gave gifts to them.. the creativity of man in history is beyond fascinating, it keeps people guessing about it all, trying to put dates on things and it’s all moving in a direction described in the Bible. Thank you for sharing this history 🙂

As an engineer and mechanic, I find this very interesting.

As to the comment made about wasted taxpayer’s dollars; I only wish our government would only “waste” money on projects like this.

No telling how much we use today that was learned by such “waste”. (Drive a car with varible cam technology?).

It’s all the things government should not be involved in at all where they use our money against us.

The Lycoming XR-7755 is 7755 cubic inches, or 127 liters, in today’s terms in size. 5000 HP@ 2600 RPMs. It was made obsolete by jets and only 2 were ever made.

Great story, cool engine. I do however disagree with the comment “wasted project” . We as aviators and humans go in many different directions to solve problems and learn. I think each genuine effort has its own rewards, this one included. I thank those dedicated people who worked on this project because in some way or another we’ve all benefited from it. Thanks again for a great job!

Regards Lino

Must have been a very big bomb it was going to carry or a large amount of small bombs! Success might have been a little overkill don’t you think, they can’t even figure out what to do with the A380 commercial acft.

Thanks for sharing, Paul. Not only was this a huge engine, a massive amount of hard earned taxpayer’s dollars was (and continues to be) spent on this and many other similarly wasted projects, unfortunately.

True that!

Wasted? I don’t think so. More thrust would be needed to fly the XB36. Jet engines were in their infancy, unreliable and fuel inefficient. Piston engines had been used for decades in aircraft. If you need more thrust, you need bigger engines. Larger cylinders, and more of them were the obvious way to go. To engineer and manufacture an engine of this scale is an incredible achievement. Hats off to the team that built this incredible beauty!